HOW TO BUILD A BENCH SEAT

in this step by step Tommy shows you how to build a bench seat. Covering hopefully everything you need to build one yourself, but if we missed anything let use know.

For this project I decided to use Oak. I purchased a board that was just over twelve inches wide from my local hardwoods supplier that fit the bill for me because the seat of this bench is twelve inches wide, but you could glue up the boards needed to create this width.

The first thing I needed to do was to cut this board down into the three pieces that would create the seat and the two uprights that would create the legs. I did this using my cross cut sled on my table saw after I cut them to rough size . The seat length is thirty eight inches long and the up rights are fifteen inches long.

After they were cut to length, I set rip fence on my table saw at twelve inches and cut them to final width.

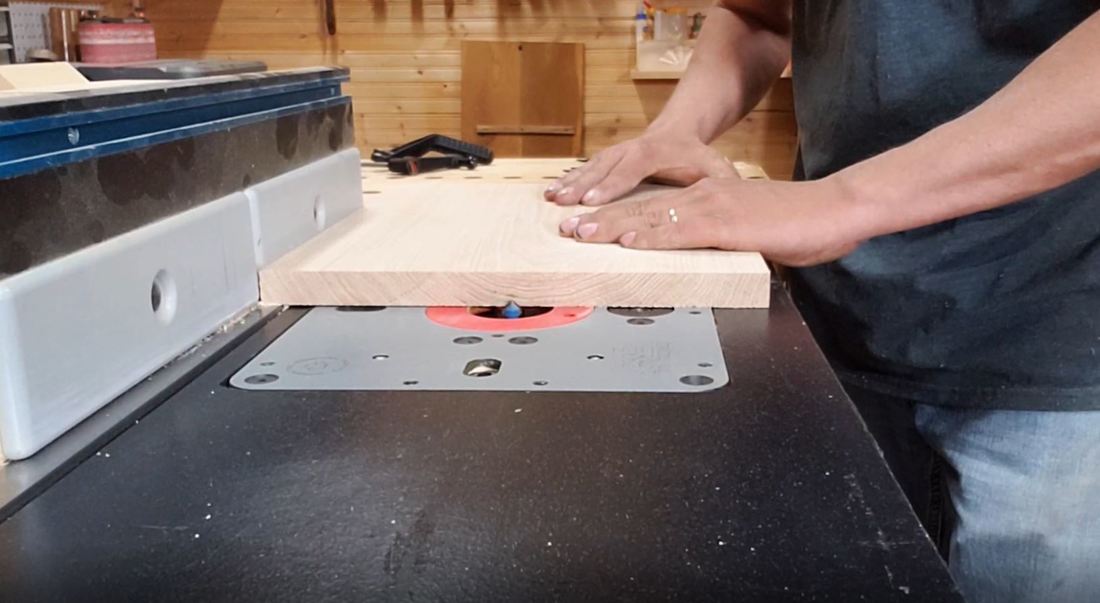

In both uprights I created a decorative design by first making a surface groove using a v-bit in my router table. This groove is center of both pieces running the full fifteen inch length. Then with a two and a quarter inch forstner bit in my drill press I drilled a hole center of this grove in the center of both uprights.

Next I wanted both uprights to have a tapper along the fifteen inch length, so using my starrett I marked one inch in to both sides of one end. Then using my yard stick I drew a line from the mark to the corner giving my tapper line.

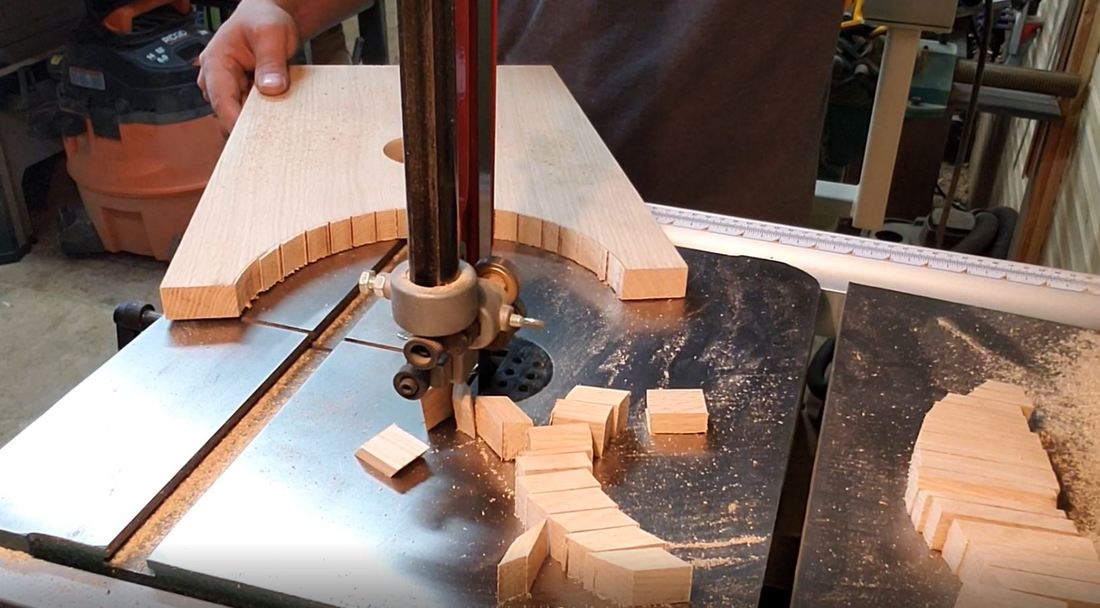

With my line established I cut it out using my bandsaw, the did a quick pass on the joiner to clean it up and remove and bandsaw marks. These cuts could also easily be done using and jig saw then cleaned up with a little sand paper.

Now I needed to creating the footings in the uprights. I did this by drawing an arch in the twelve inch end that started one and a half inches in from the edge and the top of the arch measured three and three quarters up from the bottom.

I then cut this out using my bandsaw and cleaned it up with the spindle sander. But this cut could be done using a jig saw then cleaned up with sand paper.

To create the arch in the second up right I used the first one as my template, setting it directly on top of the second one then tracing the arch with a pencil.

Now I was ready to start on the two rails for the bench. First ripping them to a width of three inches then to a length of thirty two and a quarter inches using the cross cut sled.

In both of the rails I drew a slight arch using my curve jig.

Then cut it out at the bandsaw and cleaned it up using the spindle sander.

Next I created a chamfer profile in what will be the bottom edge of the seat with a chamfer bit in my router.

Now I was ready to start towards assembly. What I needed to do is drill two pocket holes at both ends of each rail, then a series of pocket holes along each rail on the flat side of the rails.

With my holes drilled I assembled the base with the rails set in from the outside edge about an inch then clamped it together and drove in my screws connecting the rails to the up rights.

Then with the chamfer side up I placed the seat on the bench then the base on top of it. Once I had the base adjusted where I wanted it ti be I was able to screw it to the seat.

For the finish I used General finishes Armour seal, I really like this product and have had good luck with it in the past.

Copyright © 2010-2023 By Tommy P and The Shavingwood Workshop all rights reserved

The Shavingwood Workshop provides woodworking content with projects and plans. All of the content shared by The Shavingwood Workshop is shared for the sole purpose of entertainment. Anyone choosing of their own free will to reenact or recreate any of this content assumes all personal liability and or responsibility by doing so. Woodworking especially with power tools is very dangerous and can result in serious bodily harm.

The Shavingwood Workshop provides woodworking content with projects and plans. All of the content shared by The Shavingwood Workshop is shared for the sole purpose of entertainment. Anyone choosing of their own free will to reenact or recreate any of this content assumes all personal liability and or responsibility by doing so. Woodworking especially with power tools is very dangerous and can result in serious bodily harm.