- RAISED PANEL JIG -

|

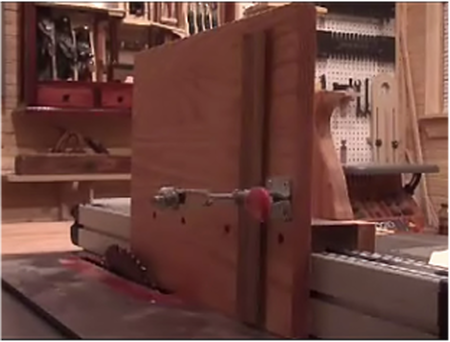

For the face of the jig I used 3/4 inch Oak that measures 15 inches in length by 12 inches tall.. I started building this jig by attaching a stop that runs across the 12 inch length of the face. Made from a piece of Walnut that measures 1 and 1/2 inches wide by 10 inches tall and a 1/4 of an inch in thickness. The stop was glued down and I used pin nails to hold it until the glue dried. Approximately 1 and a 1/2 inches in from one end. |

To achieve this I built a cradle made from 3/4 inch Oak and Walnut. The Walnut would bridge the top of the fence connecting

the face of the jig to the Oak runner on the opposite side of the fence.

|

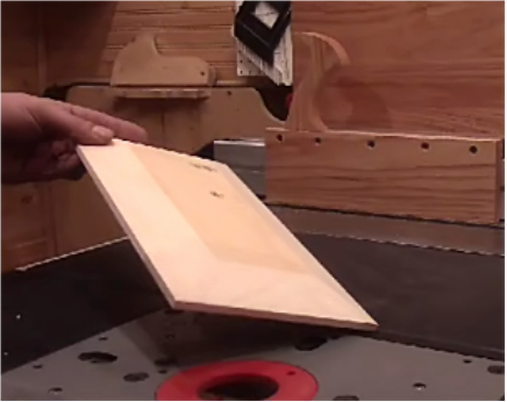

To make my first cut with the jig I set my table saw blade at about a 18 degree angle and my fence distance from the blade was set so it would leave a 1/4 of an inch of material after I make my cut. With everything set up I made my first cut, then rotated my piece of stock clock wise to make my next repeating this until all four edges where cut. |

The end result was a perfect raised panel for a door.

My choice for materials for this project where not made for any reason other than this is what I had lying around in my scrap bin.

The finish I used on this jig was a wipe on polyurethane.

Over all I am very happy with the jig, it's really comfortable to use and it does a really nice job.