|

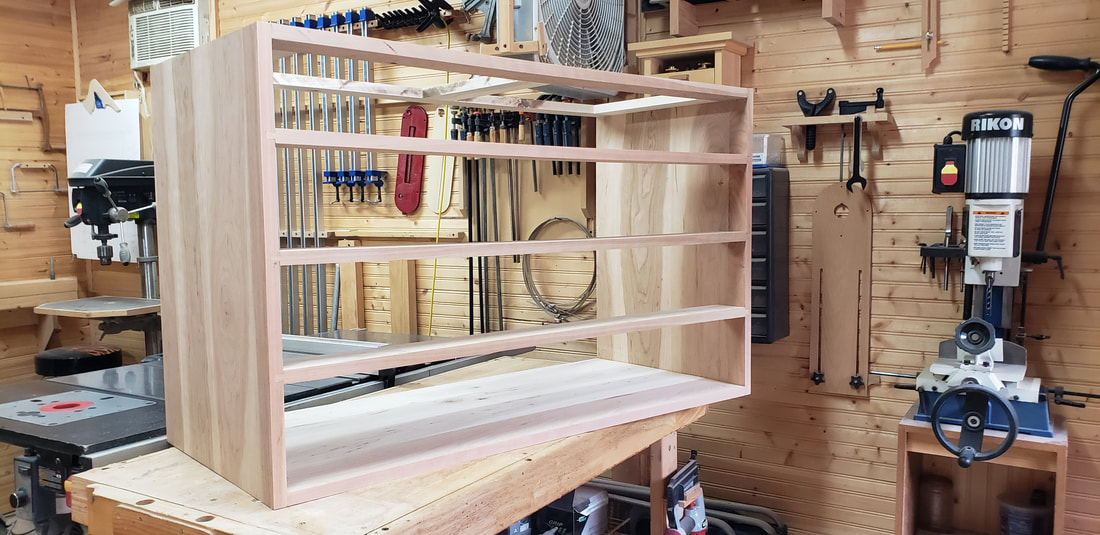

The linen press build is under way, And for this project I choose cherry for the main material with the secondary being maple. The build started with the carcass for the lower half of the cabinet, I assembled this using half blind dovetails to connect the top and bottom with the sides, and for the frame that makes up the top I used maple with cherry for the front stretcher assembling the frame with mortise and tenon joinery. Once the carcass was together I did the drawer dividers installing them to the case with exposed dovetails, and for the runners I attached them to the drawer divider with a tenon at the front using no glue and one nail to the back, the only glue I applied was at the center of the runner to allow for wood movement. With the lower carcass together I was able to create the base frame for the feet to attach too, the frame is one inch thick by four inches wide and joined with mitered corners and a half inch thick spline to add strength to the joint. I did created a profile to the edge using a scratch stock that I can only describe as sort of ogee in appearance. Once the base frame was attached I moved on to making the footings, using a simple foot design I have been using for a long time now in projects like the hall tree I built and few others. I could now focus on the drawers and dovetails where the only choice, using maple for the sides and bottoms and of course cherry for the faces. The big issue I had with this build was it is such a simple design I wanted to do something to make it stand out and the only way I could see to do it was in the details, things like the spacing of the dovetails. a small detail really but enough of one to make a big difference with out it being so much it pushed it over the top. I also spent what seemed like hours agonizing over the cherry I had trying to pick the best layout and boards for the faces, and I'm pretty happy with end result of both.

0 Comments

|

The Shavingwood Workshop Blog

Archives

June 2024

Categories |

RSS Feed

RSS Feed